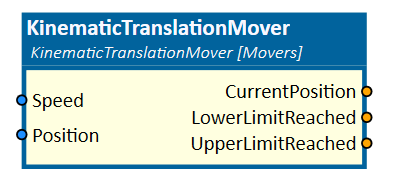

KinematicTranslationMover

This simulation component moves 3D objects or groups of 3D objects along a definable axis.

When to use

Use this simulation component if you want to move 3D objects relative to their parents along a linear axis. The translation is done by setting either the position or the speed of the movement. With this simulation component you can build a linear axle, which is moved by e.g. a servo motor.

How to use

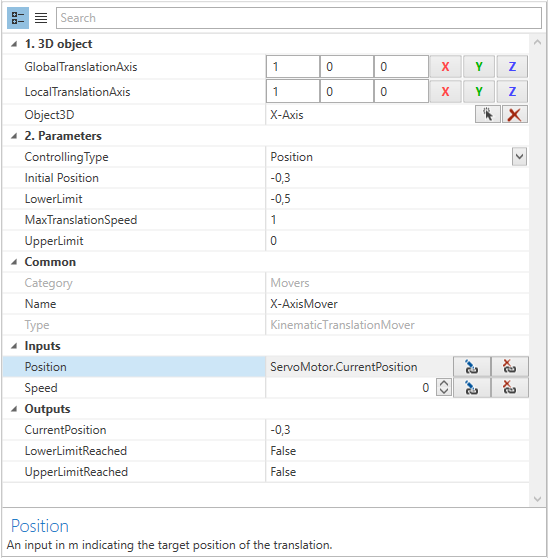

Add this simulation component from the simulation component library. At first select a 3D object or an assembly either in the 3D View window or in the Assembly Structure window using the select button near the property Object3D. Then define the translation axis either in the global or in the local coordinate system of the selected 3D object. Finally you can define the ControllingType which indicates whether the 3D object should be translated by setting the position or the speed of the movement.

Parameters

GlobalTranslationAxis

Indicates the translation axis in the global coordinate system.

LocalTranslationAxis

Indicates the translation axis in the local coordinate system of the selected 3D object. You first have to select a 3D object, before you can define the LocalTranslationAxis.

Object3D

The 3D object which will be translated relative to it's parent. The rigid body behavior of this 3D object and any children must be either None or Kinematic.

ControllingType

Indicates if the 3D object should be translated by setting the position or the speed of the movement.

InitialPosition

A value in m indicating the initial position of the 3D object.

LowerLimit

Indicates the lower limit of the translation in m. If negative infinite is defined the translation of the 3D object is not limited.

UpperLimit

Indicates the upper limit of the translation in m. If positive infinite is defined the translation of the 3D object is not limited.

MaxTranslationSpeed

Indicates the maximum translation speed in m/s. When the parameter ControllingType is set to Speed, the input Speed is multiplied by this factor.

Inputs

Position

An input in m indicating the target position of the translation.

Speed

An input indicating the speed of the movement in fractions of the parameter MaxTranslationSpeed. 1.0 means 100% of the parameter MaxTranslationSpeed.

Outputs

CurrentPosition

Outputs a value in m indicating the current position of the translation.

LowerLimitReached

Outputs a value indicating whether the lower limit of the translation is reached or not.

UpperLimitReached

Outputs a value indicating whether the upper limit of the translation is reached or not.

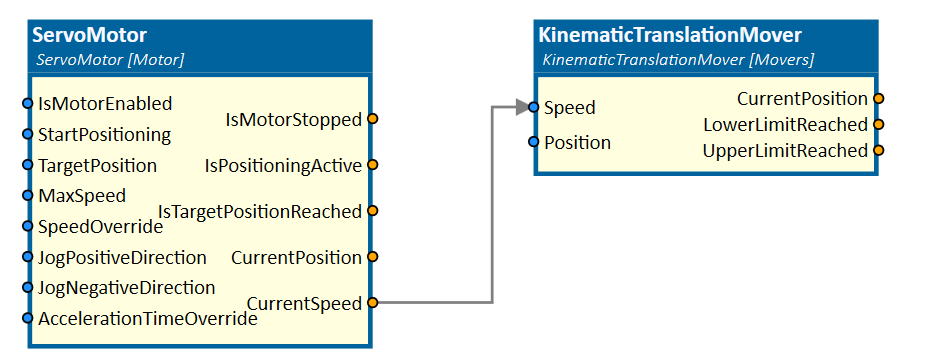

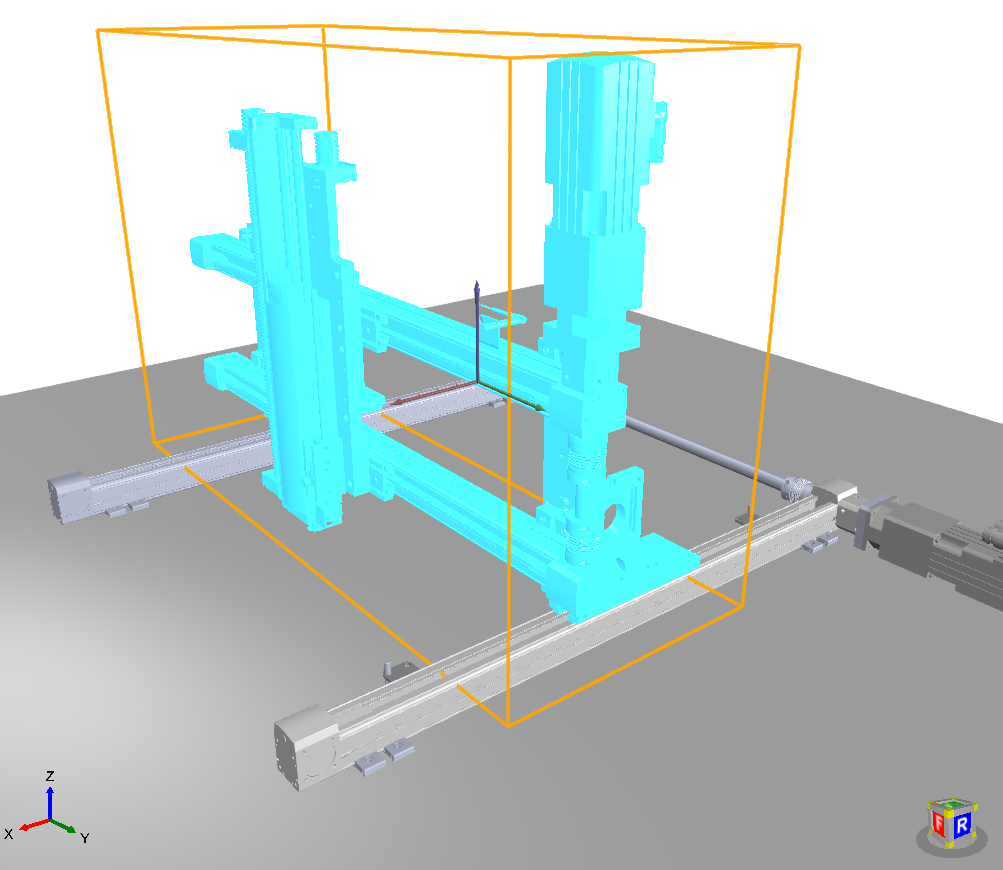

Example

In this example, the position output of a ServoMotor simulation component is used to translate the selected 3D object group "x-axis". The positive direction of the movement is in the direction of the global x-axis.

Due to the fact that the x-axis is designed at an initial position of -0.3 m, the corresponding parameter InitialPosition is set to that value. The mechanical stops, UpperLimit and LowerLimit, were set to 0 m and -0.5 m.

Further Information

For more details visit the Video Guides section, where you can find a video guide demonstrating this topic under Kinematization of axis systems and gantries.